Heh all! Well, because of all your help, we got the votes we needed and qualified to be considered for the Mission Main Street Grant! I can’t thank you enough for all your support! We got way more votes than we needed! Now, I am long past due giving a shout out to a really amazing lady who is helping people all over the internet with her cooking channel. Hands That Cook offers all kinds of recipes, tips and demonstrations that are easy to follow. She has a wonderful knowledge of cooking skills and a heart to share them with those who wish to learn. Though she likes to remain anonymous, the videos and voice are warm and inviting and I know that you will get a lot out of them. She has a diverse following who obviously love her to pieces. Hands That Cook ordered one of our Oklahoma Pastry Cloths™ and it was certainly a pleasure working with her. She liked our product so much that she did a show about a 100 year old pie crust recipe that she uses while offering a great review of the pastry cloth. You can enjoy it here: It is so wonderful to see how our products are making life easier and pleasant in kitchens across the country and even in other countries. That is our goal!! We tried Hands That Cook’s recipe for pie crust and it was wonderful.  And of course it had to be an apple pie. Yummy! Thanks to Hands That Cook for a great recipe and a wonderful testimonial.  |

|

| |

|

Oklahoma Pastry Cloth™ Company on Facebook

|

|

|

|

|

Archive for the ‘So You Have To Make It Educational!!’ Category

Shout Out

Monday, June 29th, 2015

Waxing Commercial Cheese

Thursday, October 10th, 2013

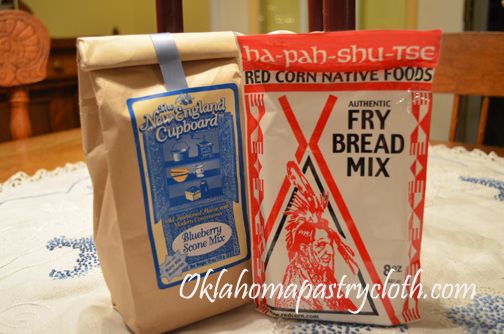

You know I can’t resist a sale, And so begins this shopping tale. I found a bargain sure to please, A dollar for a block of cheese! I purchased 12 and paid my dough. I’ve showed you how your cheese may can, I followed directions to a ‘T’ And so you see (you’ve got to get it!) No groans from the peanut gallery out there!! I can’t resist a little verse…a very little verse! I thought that I would show you, step-by-step how to preserve cheese that you find on sale. Mine has been sitting at room temperature for four months now and we are using it regularly. Mr. Fix-It likes this cheese on crackers and sandwiches because as it sits, it ages. Now it tastes like expensive, aged, sharp cheese. But first, I’d like to remind you about the giveaway going on.  Just be sure to leave a comment below in the comment section and you’ll be entered to win our fry bread mix and a package of our blueberry scones (complete with a can of real, Maine wild blueberries). The drawing will be October 18th.   OK. Back to cheese. Any brand of cheese will work, but I happened to find the REALLY cheap kind. I grabbed mild cheddar, provolone and longhorn. All are relatively mind flavored cheeses so that when they age, they don’t become too sharp.  I cut the blocks in half to make 4 oz blocks for easier waxing.  Carefully wipe each block with white vinegar to clean. If you do not have vinegar, you can use a brine mixture of 1 tsp salt to 1 cup of water.  Place the cheese blocks onto cookie sheets, wax paper or paper towels and allow to dry for 48 hours. You can turn the cheese if it is not on racks. I am using metal cookie racks here, but I think that plastic racks would be better. The metal can rust or oxidize and leave lines on the cheese. I am purchasing some plastic racks for future use.  After the cheese has dried, using paper towels or cheese cloth, wipe excess oil off of each block.  I melted the wax in a double boiler. You can purchase cheese wax online at the New England Cheese Making Supply. The wax is supposed to get as hot as possible to kill any spores and the only way to get it really hot is to put the pan directly on the stove eye on high, but that is very dangerous as the wax can catch fire or even explode. Plus, you can really get burned. So I did some research and many people are using a double boiler and getting it hot with boiling water beneath it. It is the safest way and seems to work fine. You can make a double boiler, if you don’t have one, by placing an empty tuna can in the bottom of a sauce pan, filling the pan with water and then placing a smaller pan onto the tuna can to keep it from dropping down into the first pan.  Or, you can use an old cake pan, fill it with water and set your pot into the water. By the way, I went to our local Big Lots and bought this sauce pan for $3. I just keep the wax in it and let it harden after melting to use the next time, adding more as I need. To store, I keep the lid on it so that no dirt gets inside.  When the wax is hot to almost boiling or is boiling, dip one end of each of your cheese blocks into the wax to halfway up.  Turn the blocks to the undipped sides and let them rest to harden  It only takes about a minute for the wax to harden where you can touch it. Pick the cheese up by the wax end and dip the unwaxed end. Place the block onto the end with the hardened wax so that the new wax can harden. Continue this process until you have waxed each end four to five times.  Place the waxed cheese in a container and into a room that is dark and cool or into a pantry where it can be easily accessed. Every few days, turn the cheese to a different side. Sometimes, the cheese will weep oil or water. It is still ok to use. I found that storing it on paper towels or cheese cloth helped absorb any weeping. Also, in some cases, the wax will thin and so you will need to wipe it clean and dip the block a couple of more times. If you see a dark patch under the wax, it is probably mold which is the result of a pin sized hole or other disturbance of the wax surface. You can use that cheese immediately, washing it and cutting off the molded part.  When you decide to use a block, use a knife to pry one end of wax off of the cheese. The rest just lifts off. Wash the wax in hot, soapy water and be sure that any pieces of cheese and oil are removed. Put the wax into your wax pan to reuse on your next batch.  The cheese can be grated  It can also be sliced or cut into cubes. Because it is sharper, it is also drier. So there you go!! Now you can wax poetic too….and if you want to send me your poems, I put them up at the blog! 🙂 Don’t forget to leave a comment to enter the giveaway!   |

|

| |

|

Oklahoma Pastry Cloth™ Company on Facebook

|

|

|

|

|

Bull Shoals – A Little Place Of Heaven

Friday, August 23rd, 2013

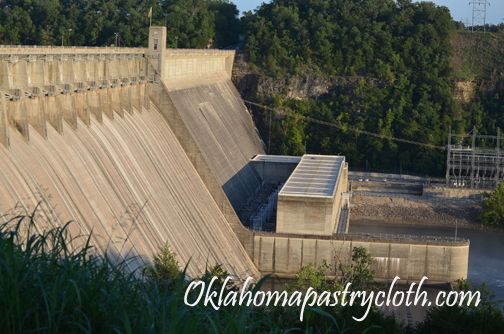

Mr. Fix-It and I just got back from our favorite place in the whole world. It’s simple. It’s lovely. It’s laid back. And it’s cheap!! (That’s the best part) We love to visit the Bull Shoals, Arkansas area which includes Cotter, Flippin, Mountain Home, Fairview and Lakeview. We stay in various places whenever we go but our favorite place to stay is in a tent at the Bull Shoals State Park campground. What a gorgeous place to be!! The deer are so numerous that you can nearly walk up to pet them and the White River is cool, quiet and serene as fly fishermen silently cast their lines to snag hungry trout. It’s just God’s Creation at its best. We only spent a few days in the area and actually stayed at an historic and popular resort called Gastons White River Resort since our stay was so short. We plan on going back in the Fall to camp for a longer time. But I thought that I would post some photos of the area just for you to enjoy.  First of all, I bet it’s been a long time since you’ve seen one of these at a motel! Gastons is still using keys for the doors to their cabins. Kinda quaint – and Psycho-like. 🙂  We woke up to this scene out of our window. It just did my heart good.  We skipped over to Cotter for a few hours. The spring there and the park are just so pleasant. This is the Cotter Bridge which was built in the 1930’s.  The dam at Bull Shoals was built in the 1940’s and harnesses the White River for electricity, as well as for Bull Shoals lake, a huge recreational lake that spans Arkansas and Missouri.  On one side of the dam is Bull Shoals Lake  And on the other side of the dam is the White River. I’ll give you three guesses why they call it the White River!  On our exploration, we had to stop the car in the road to allow this aimless wanderer time to mosey across without a care in the world.  In the town of Bull Shoals, I caught this advertisement and thought it was a hoot. Pretty creative!!  There has been so much rain in Arkansas that the flowers are gorgeous. The drought seems to be over in that part of the state, anyway. This hibiscus was spectacular. If you get a chance to head down Bull Shoals’ way, you should! And bring a tent for camping at the state park! (who needs a big, expensive camper!?) You might even get a raccoon or two to join you for dinner!  |

|

| |

|

Oklahoma Pastry Cloth™ Company on Facebook

|

|

|

|

|

Getting Down To Business: A New Give Away!

Monday, April 1st, 2013

Everything is back to normal. We’re back to work and all WAS going well until the big press died. Now, it is lying in pieces, looking like a destroyed robot from Star Wars. Mr. Fix-It is doing the surgery but a thermonuclear discombobulator is needed and the only one that could be found must be ordered from…where else?…China. Actually, it is called a heat resistor thingy. Evidently, it’s an important thingy, too. Ah, technology! We have had a number of emails just recently, dealing with the subject of shipping. Personally, shipping is the bane of my existence. I wish that we could ship everything to everyone for free. But alas, I don’t do the lottery and haven’t won any millions so we can’t afford to give away the farm. Shipping expense is a reality with which Creating Concepts, Enterprises must deal. And on top of everything, unfortunately for all of us, shipping costs have gone up. We do not use UPS or FedEx because their charges for the size shipments we send out are ridiculous. In fact, their charge can be as much as $15 over what the US Postal Service charges us. And so, we use the US Postal Service Priority method almost exclusively. For international orders, First Class is used. First Class packaging is not available for the states. Everything is done by weight and for online orders, PayPal does its best to estimate as close as possible to accurate shipping charges. Sometimes, it misses the boat and nearly always it goes against us rather than the customer. In fact, we were rather sick awhile back when an order to Australia was estimated at $11 by PayPal and the actual shipping cost us $22.50. Not good. The fact is, shipping is high. Phone orders are more of an exact science for us because as soon as an order is processed and ready to ship, the customer credit card is charged with the exact amount on the shipping label. If you plan to order, doing so with a credit card by phone at 405-275-5639 will be the most accurate route. I, personally, feel badly when someone is unhappy with a shipping cost that they perceive is too high. A larger Oklahoma Pastry Cloth™ or multiple pastry cloths can be heavy and so cost more to ship. The mixes add up in weight as well. It doesn’t matter what box or bubble mailer is used, the weight is still the same, the location is assessed and the price goes up accordingly. Our Oklahoma Pastry Cloth™ is made of a heavy weight cotton, unlike the cheaper, lighter brands, so that it will last for years and years. It is not meant to be a throw away item but is meant to be a family treasure. So hopefully, this will better explain our shipping policy. I understand the groan of financial agony when a customer sees that shipping charge. It seems too high. But in order to use the US Postal Service, we have to pay the price – their price. We appreciate your understanding.   It’s time for another giveaway! And this is no April Fools joke. Since canning season is just around the corner, we are giving away a nice set of canning tools ready to be used! Starting today, leave a comment on any of the blog posts and you will be entered. If you have never posted at the blog before, don’t worry if your comment does not show up immediately. New posts must be approved by the moderator and then your post can be seen. The drawing will be two weeks from now on April the 15th – TAX DAY! Yayyyy. Good luck to everybody!!  |

|

| |

|

Oklahoma Pastry Cloth™ Company on Facebook

|

|

|

|

|

|

A Sick Bed Craft

Wednesday, February 20th, 2013

In-FLU-enza…H1N1…Tamiflu…all words that none of us actually care about or even think about – that is – until we stumble into the doctor’s office, eyes glazed, throat that could only feel worse for a fire eater and muscles that scream four letter words at us, as we try to use them. THEN, the flu becomes a reality and a reason to think seriously about finding a sky scraper from which to jump. Such was the past week for Mr. Fix-It and me. He succumbed first. I knew he was sick when he willingly grabbed his keys and left the house early last Sunday morning to hit up the AM-PM clinic for drugs. ‘Mr. Fix-It’ and ‘getting medical help’ are not usually in the same sentence. Since he only had a fever of 99.9, after a nose swab, Mr. Fix-It was rather taken aback when the doctor forced a mask over his face and admonished him not to go anywhere, including work, for 5 days. The doctor was stern in his warning and typed up a letter to give to the boss. He told Mr. Fix-It that he was highly contagious and so he came home, not entirely convinced that he was really THAT sick. But then, Sunday afternoon hit. My hubby was a mess. His fever was quickly inching to 104º and I was frantically making preparations to get him to the hospital. I had tried everything…tylenol, ibuprophen, tepid bath, alcohol rub and then I remembered an elderly doctor’s method quite a number of years ago when our son’s fever had gone to 105. I filled plastic bags with ice, wrapped them in towels and put them under Mr. Fix-It’s arms, on his stomach and on his forehead. Magically, the fever dropped to 102º. All evening I battled the fever and Mr. Fix-It’s irrational statements that let me know he was NOT all with me. By midnight his fever broke and he actually slept while I transferred myself to the couch, hoping to avoid the disease. About 3 am I woke up shaking from head to toe, teeth chattering so hard that I could not keep my mouth shut and throat literally shooting flames. Oh no. Somehow, I made it to the bedroom and crawled into bed next to my ailing husband. I figured that I might as well be comfortable now that I had caught the germs. Of course, I woke him up with my shaking and he crawled out of bed to get me some tylenol and water. I thought I was going to die. We figure that Mr. Fix-It brought the germs home from the VA Hospital where he had done a computer installation the week before. Ten days is the incubation period and it had been ten days since his visit. I am sure that I picked the germs up from his clothes or from him. Who knows? All I know is that neither one of us has had the flu in years and years and years and years and so the ferocity of the disease was rather disturbing. It has taken both of us over a week to get back to normal. But, as always, I could see that there was a humorous side to our plight. I made it to the doctor as well…just our family doctor…and I found out that just the word ‘flu’ nearly tatoos an ‘F’ on your forehead and hangs a sign around your neck that announces, “Unclean! Unclean!” I was told to wear a mask throughout my visit and the nurse who swabbed my nose (might I add that this is one of THE most unpleasant tests on the planet – because your sinuses are already swollen and raw without a q-tip being twirled around the membranes like a chimney sweep’s broom!) barely stuck her head back in the door and said through clenched teeth, “It’s flu!” And it wasn’t just the flu-flu. It was the BAD flu. As I left the room with prescription in hand, the cleanup crew was already disinfecting everything I had touched. Even the woman who checked me out, handed my Visa card back to me, washed her hands, grabbed the pen I had been using, disinfected it and wiped the counter right in front of me. As I stepped back, I felt like I had smallpox. I slunk past ogling patients, bemasked and humiliated. Two days later, still diseased and miserable, I needed to somehow get an order to a friend, who had come in from out of town. We discussed the logistics of this feat without germs and it was agreed that Mr. Fix-It, who was well on the road to recovery, would drive me to a designated meeting place. He did so and when we arrived, dear friend stepped around her vehicle and waved, at a safe distance of 50 or so feet away. Mr. Fix-It got out of our vehicle, placed the box of goodies onto the pavement of the parking lot between our car and Friend’s and proceeded to soak the box with spray Lysol: Bottom, sides and top. The contents had already been lysol’d. I was looking around for Homeland Security to come swooping in with a bomb squad and handcuffs for each of us.  We got back into our car and Friend picked up the box to place in the back of hers. Hopefully, all germs were murdered by Lysol drowning. Now, I have to tell you that being sick is a boring state of being, but thanks to this same Friend, I was given a fun craft project that served to pass my time in bed and produce lots of little bows. She sent me an email with directions for making tiny bows that are so handy for a multitude of projects. And, heh, when you are running a fever and eating popsicles a new craft is a welcome distraction!! All you need is some 1/4″ ribbon, preferably a light weight or organza type, scissors and a four tined fork.  First, begin by running the ribbon under the first tine, over the second, under the third and over the forth.  Pull the ribbon under the fourth tine and pull it all the way to the first tine.  Now, go over the first tine, under the second, over the third and under the fourth.  Push the ribbon up to the end of the tines to keep it tight.  Continue the process until there are either two or three (depending on the size of bow you want) wraps around the outside tines  Clip the end of the ribbon that is attached to the spool and now run a fresh ribbon end up through the tines between the second and third one and in front of the first row of weaving  Pull up other end of this ribbon and clip off, leaving enough that will make it easy to tie  Pull the two ends up, gathering the center of the woven ribbon together, and tie at the center in a knot  Slip the bow off of the fork and clip off extra ribbon. The bottom bow was done with two rows and the top one was done with three rows  Use to decorate cards, hairclips, clothes and anything else you can think of!  |

|

| |

|

Oklahoma Pastry Cloth™ Company on Facebook

|

|

|

|

|

|

Tutorial on Making Soap

Friday, September 14th, 2012

Whew. Got lots of pictures for this one and it has taken a bit to get them cropped, size-adjusted and signed to get them up. Sorry for the delay. But here we go! First off, I won’t be giving a recipe here simply because I am not at liberty to give this particular one. It is actually a copyrighted recipe that I doctored for my purposes. However, if you go online and look up recipes for Castile Soap, you will find lots of them and you can just choose which one you would like to try. The process is still the same. This is true for vegetable oil based soaps too. This process is the same, no matter what oils you use. The trick is to stay within exact weights of ingredients, according to each recipe. The oils might include coconut oil (which gives a nice lather), shea butter, olive oil, grapeseed oil, almond oil, etc. Experiment and see what you like. At first, I wasn’t worried about a recipe. I was hesitant to try making soap because I needed to see the step-by-step process so that it wouldn’t be quite so intimidating. I’m a visual learner. So, I decided that I would put the process up in pictures for anyone out there who, like me, needs to see what the steps look like. Tools you will need: A large, stainless or enamel cooking pot Making the lye solution: This soap is made with a lye and water solution. The solution gets extremely hot – dangerously so. When ready to use for making soap, the lye water will need to be between 95º and 98º and so it is fine to make it the day before to allow it to cool down. It is much easier to then raise the temperature back up from room temperature then it is to wait around for it to cool down from 200º to the correct temperature.  Everything in soapmaking is done by weight. For example, if a recipe calls for 32 ounces of water, that actually means 2 pounds by weight. Or 8 ounces means 1/2 pound, not one cup. I use a digital scale to measure because it is so easy to adjust for the weight of the recepticle in which ingredients are placed. To measure the water, I place the pitcher on the scales before they are turned on. When I hit the “on” button, the scale accounts for the pitcher and zeroes out the weight. I can now add the water and get the exact weight of water I need without getting confused by the weight of the pitcher!  Lye can be found at Ace Hardware stores, but you have to ask for it. They keep it locked in a back room. There are other stores where it can be purchased too, and if you are making lots of soap, there are chemical companies that will sell it in large quantities. The chemical name for lye is sodium hydroxide. Lye is very caustic and very dangerous, so treat it with respect. Wear old clothes, an apron, rubber gloves and a shirt that will cover any exposed arm. Safety goggles are a good idea too, to avoid burning your eyes. In a separate container with a lid, weigh out the amount of lye listed in the recipe that you will be using. Do not touch it!!  Making the lye solution is best done outside or in a garage with good ventilation. Adding lye to water causes a chemical reaction that emits the most noxious fumes that can overcome you. Keep your face from being directly over the pitcher and if you have to, wear a face mask to filter the fumes. Some people are quite allergic to them. Lye is always added to the water, not the other way around. If water is added to the lye, it can cause an explosion kind of like a volcano and then you are in real trouble!! Lye will eat whatever it touches, (ok..so that isn’t very scientific terminology – it corrodes!) including your skin. So remember: Lye to Water!! If you happen to get some lye mixture on you by accident, immediately run cold water over the area and wash with vinegar to offset the reaction. Now, to make the lye water, pour the premeasured lye into the premeasured water in a steady stream, stirring as you pour to dissolve it well. The mixture will start giving off a vapor and will get extremely hot. You will not be able to touch the pitcher. Continue to stir until the lye is dissolved and then place the lid onto the pitcher, turned so that the spout is open to vent. Either leave the mixture outside on a place where no child or animal can reach it, or put into a shed or garage where there is no danger of disturbance. If there are other people in your household, label the pitcher before use with a skull and crossbones, a big red “Danger” and “Poison” so that nobody mistakes it for anything other than what it is!! Note: Occassionally check your solution and give it a stir to make sure that the lye remains dissolved. It can settle to the bottom and leave a hard block that is difficult to break up if you do not stir it once in awhile.  Prior to making soap, everything should be prepared, weighed and ready before anything else is done. You won’t have time to do that once the process has begun. Weigh all tallow and/or oils into the stainless pot. Then, if you are using essential oils or fragrance oils, have those measured and ready and off to the side. If you plan on using goat’s milk, have that measured and it helps if it is partially frozen or at least very, very cold. It doesn’t hurt to have it in a small container that sits in a bowl of ice, to keep it cold until use. Just a hint: I freeze the goats milk in mini muffin tins that equal 1/4 cup each and then pop them out and store in a freezer bag. I can then grab however many I need for a recipe and place in a bowl ready for use. If you plan on using herbs or colorants or spices, those all need to be weighed ahead of time as well. Line your items up in order of placement according to your recipe to make it easy to grab and dump. You will be working fast and some of the essential oils may cause you to have to really work fast as they accelerate tracing in the soap.  Molds must be prepared ahead of time as well. You can use practically anything for a soap mold! Here, Mr. Fix-It made me a high-falutin’ contraption that is great, but you can use a cardboard box, like shoe boxes. Or you can use a lenth of guttering with ends put in place for a fluted soap bar. Use your imagination! Whatever you choose to use must be lined with plastic and one side of a white trash bag or a cut up large, plastic shopping bag works great. Here, I am laying the bag over the mold to press it down into the mold. I will do that by putting the plexiglass pieces that Mr. Fix-It cut for the inside of the mold. When the soap is firm, the plastic acts as a handy way to lift the soap out of the boxes or other items.  The lining is in place and the dividers are set to the side to put in after the soap is poured into the mold.  Now for the fun!! Heat the tallow and/or oils on low heat to melt slowly. Don’t heat too fast because then the oil gets too hot. Stir occassionally to break up any tallow chunks. When most, but not all, of the tallow is melted, remove the pot from the stove and allow the rest of the fat to melt off of the heat. The mixture will be hot enough to do that and you can stir it some to continue the process. Using a thermometer, check the temperature. It will probably be over 100º so there will be some cooling time required.  In the meantime, place hot water in the sink or in a dish pan and put the pitcher with the lye solution (that will be at room temperature), into the water. I keep a tea kettle of boiling water available to add to the dishpan to raise the temperature of the water, if need be. Using the thermometer, check the temperatures of the lye solution and the fats, aiming for between 95º and 98º. I know this sounds tedious and complicated, but you would be surprised how fast it goes. It isn’t that difficult to get both temperatures in sync.  When both the fat and the lye solutions are between 95º and 98º, begin pouring the lye water into the fat, stirring with a long handled wooden spoon and making sure that the lye water is pouring in a steady stream. Don’t dump it in all at once. Here, Mr. Fix-It is helping so that I could take pictures and he refused to wear my gloves, but it is a really good idea to wear rubber gloves so that you don’t get splashes on your hands. Continue stirring and pouring until the pitcher is completely emptied. Keep stirring and stirring. Go around the edges of the pot, stir into the middle, go back and forth – you are getting the lye solution well incorporated and you don’t want there to be any pockets of lye that are not mixed. The lye and the fat will start reacting with each other and the mixture will become pretty hot at first, hence the long-handled spoon!!  This is where an immersion blender comes in really handy. The blender really incorporates the lye solution into the fat well. You can blend for a minute and then stir and then blend, etc. because you don’t want to get your blender overheated. Move it around the pot like you would the spoon and cream all areas of the mixture.  The soap will begin to thicken, kind of like pudding. The term ‘tracing’ describes what it looks like when you take the spoon out of the mixture and drips and runs stay on top of the surface or you can draw a circle in the surface and it doesn’t disappear, like the surface of hot pudding.  At this point, you are ready to add the goats milk, essential oils, fragrance oils, herbs and colorants. I add the milk first and then the oils, using the immersion blender to blend well.  Next goes in the herbs or flowers and colorants. Here, I am adding some dried and rubbed sage from our garden. If you want to add color, you can use natural items to achieve that without having to use commercial colors. Cocoa works well to make a soft brown while paprika makes a neat orangish tint. Tumeric is another spice that colors. You can also add oatmeal pieces for a soothing soap.  The soap is now poured into the mold or molds and I use a silicone spatula in the pot to accomplish this.  The dividers are added into the mold and I am having to work fast because this recipe sets up fast.  The lid to the mold is immediately put into place and I tap the whole mold onto the counter to evenly distribute the warm soap. If you are using a box or other item for a mold, you can use a piece of cardboard with a towel placed over it to cover your mold. The purpose of the cover is to let the soap cool very slowly. Do not lift the lid to peek. Leave the mold alone for 24 hours, at which time you can open it and lift the soap out by pulling up on the edges of the plastic liner. If you are making some of the vegetable oil soaps, hardening may take longer than 24 hours. My mold releases the ends of the mold and I can slide the whole soap block out and then separate each bar from the dividers. The soap will be very soft, so you have to be careful. At this point, you can cut your soap into bars and you can slice the very tops off where a soda ash residue may have collected, to make a nice, smooth surface. You want to remove the soda ash because it is hard on your skin. Again, vegetable oil based soaps may not be ready quite this quickly to cut.  And voila! Soap! These bars will cure for about three to four weeks before they will be used. As the bars cure, the chemical reaction continues and improves the quality of the soap. You can carve the edges of your soaps for a softer look if you like. So there you go. Isn’t that neat? I feel like my great-grandmother, only she used a big, cast iron pot and made enough soap for a year in one batch!!  |

|

| |

|

Oklahoma Pastry Cloth™ Company on Facebook

|

|

|

|

|

|

Rendering Tallow For Soapmaking

Thursday, September 6th, 2012

|

This weekend I finally did what I’ve been wanting to try for over a year. I made soap! Not in a class. Not at a farm. In my own home with Mr. Fix-It at my side. It was awesome!! I now have 36 bars of soap that smell divinely of peppermint, rosemary and real sage. I seem to be that kind of person who has to have the lightbulb go off (In the words of Mork from Ork, “The time is right. The Gestault is now!”) before I can do anything new. There is something in me that is afraid to dive into the unknown unless I have all my ducks in a row. (I didn’t mix those two metaphors too badly. Ducks dive. OK?) I have to be ready, no matter how long it takes. Well, it took me a year to make soap and in that year, I watched videos, read books and still required actually seeing it done right in front of me to give me the courage to take a stab at it, myself. Just as an aside, my attempt at learning to drive in high school comes to mind as an example of my light bulb theory. My dad had bought a brand new 1965 Beetle bug – known to all you young’ns as a small, round, Volkswagen car. It was a soft green with black, rubber interior that never lost that rubber smell. It was a 4 speed manual in the floor and only knew ‘roll backwards’ when paused at a red light on a hill. My dad worked and worked with me, attempting to run me through the gear changes without eliciting a painful grinding that was a combination of the car’s innards and my father’s teeth. Every outing erupted into my father yelling in abject terror and me crying buckets of tears at my obvious stupidity concerning vehicles. I hated that car and I hated the lessons. Finally, I refused to ever learn to drive the monster. A few months later, I was sitting in my room, doing homework, while my parents had gone doing what parents determine to do in town. As I sat at my desk, I put my hand down beside me and made an ‘H’ – Forward: First gear, Backward: Second gear, To the right and forward: Third gear, now backward: Fourth gear. Press down and back: reverse. I tried it again in the air beside me. Hmmmm. I trotted downstairs to the key holder beside the garage door and grabbed the keys to the Beetle. Inside the car, I put my foot on the clutch and practiced first, second, third, fourth, reverse. First, second, third, fourth, reverse. I opened the garage door and started the car. I backed that car out as pretty as you please and tootled all over the subdivision without a hitch!! And then, I put the car back into the garage, went back upstairs and continued to study. My parents never did know what happened. I just started driving the car and drove it for years. I loved that car! So now, I’m hooked on soap making. It is just fun. Addictive is more like it. I took pictures and thought I would do this in two posts. This first is on how to render the tallow that is used in many soap recipes. There are also recipes that use other oils instead, but I wanted to make a nice, firm Castille soap with a tallow base because of its quality and longevity of use. I get fat from a local packing house and at the suggestion of a lovely soapmaker, Linda, I always ask for the kidney fat because it is the most pure. Start off with at least twice the number of pounds of fat as tallow that you want to produce. So if you need 4 lbs of tallow for a recipe, start with at least 8 or 9 lbs of fat. And it doesn’t matter if you make too much. The tallow can be frozen and kept for another batch of soap or mixed with butter for an unbelievable pie crust or biscuits if you don’t care about calories (unlike me)!! And birds like it too. They need the calories worse than I do.  Cut the fat into small pieces. If you have a meat grinder or if the packing house will grind it for you, this works great and makes the fat render so much faster. In a large stock pot, add a quart of water with 2 tbsp. salt. Heat on medium-high to high heat and start adding the fat, a little at a time, stirring as you go. Bring to a boil and cover with a lid, leaving the lid a little off to the side to allow air to vent. If you can’t get all of the fat in at once, just add as the fat starts to melt and leaves more room.  When the fat starts to rise to the surface, lower to the heat so that the mixture is at a low, slow boil, occassionally stirring things around and pressing big pieces to squash them. Cook for at least 4 hours to get plenty of tallow separated. I just let it go and do other things, checking occassionally. I do add a little water if it gets too dry. Be sure that your heat is not too high so that nothing burns or scorches.  Pour the contents of the pot into a colander in a large bowl or pot or plastic container, a little at a time, to strain.  Press the fat in the colander with a spoon to release any extra liquid. Toss the globby fat.  Allow the liquid to come to room temperature. Once cooled, place in the frig covered with plastic wrap or a lid. Refrigerate until the next day.  The next day, the mixture will have separated with the tallow at the top, some gray, yucky stuff in the middle and water at the bottom. Lift the solid matter out of its recepticle and throw away the liquid.  Scrape off the gray matter to separate the pure tallow.  Store the tallow in freezer bags in the refrigerator for up to two months or in the freezer indefinitely. Now you are ready to make soap, candles or anything else that requires tallow! It’s Little House on the Prairie time!! MB |

|

|

|

Dried Ears

Tuesday, July 31st, 2012

Well, it appears that my internet is totally hosed for who-knows-how-long. It has been down and I have waited patiently for a reawakening, only to find out that the company is down all the way into Kansas!! Somebody cut a cable. Dear Mr. Fix-It got me hooked into a mobile unit and so I get to write a really fast post!! Today, the subject is “Apricots”. Growing up, I loved dried apricots. We kids would get a bag and devour them instead of candy. I still love them today and I still call them what we used to call them, “Dried Ears”. Seeing my cousin recently, she affirmed that THEY call them dried ears as well! You can’t deny that dried apricots look like something some faraway, cannibal tribe collected from unsuspecting captives, not to mention that which Van Gogh sent to his lady love. OK, so now I’ve really made them appetizing, eh? Apricots are a member of the same family as peaches, plums, apples and pears but are most closely associated with plums. They grew wild in China as long ago as 2000 BC and it was the Chinese, through the silk and spice trade, that brought the fruit to the Middle East and Mediterranean countries. Romans made the apricot trees part of their culture around 100 BC as did the Greeks who called them, “the golden eggs of the sun”. By the Middle Ages, apricots were being cultivated throughout Europe. The Spanish brought the fruit trees to the New World, first planting in Mexico and later in what is today’s California, which is the leading producer in our country today. Because of our climate in Oklahoma, apricot trees produce quite well and quite prolifically. If you remember from the past post on the bunnies, Sir Flying Ace’s dog found those bunnies in an underground nest beneath his apricot tree. Last month, I joyfully emptied that tree of as many of the jewels as I could reach and then Sir Flying Ace brought me another sack that he had gathered. Mr. Fix-It and I have a young apricot tree, but it will not be ready to produce for another two years. From Sir Flying Ace, I got enough apricots to make some amazing jam, some baby food for the grandbaby and a goodly amount of dehydrated halves for snacks and dried apricot fried pies. I thought I’d give a few pictures of what that included. Apricot Jam 5 exact cups diced fruit (about 3-1/2 lb. fully ripe apricots) 1/4 cup fresh lemon juice 7 cups sugar, measured exactly into a separate bowl 1 box SURE-JELL Fruit Pectin 1/2tsp. butter or margarine  Apricots are easy, easy to prepare. They are used – minus the pit – skin and all. All you have to do is make a cut all the way around the fruit, to the pit, and then pull the halves away to lift out the pit. The pit doesn’t even stick.  I use a food processor to chop my apricots. I use the pulse feature so that I don’t liquify them and make the pieces too small.  The chopped apricots are put into a large pot with lemon juice and the SureJel is sprinkled onto the fruit and stirred in until well dissolved. The butter is then added to keep frothing down.  On medium-high to high heat, the fruit is brought to a rolling boil. At this point, the sugar is added consistently and quickly as you stir. I use a wire whisk to stir the jam as I pour in the sugar. It is important to have the sugar measured out ahead of time because you will not have time to do that once the fruit has started boiling. Anyway, once the sugar is stirred in well, bring the jam back to a rolling boil and boil for one minute.  After one minute of boiling, remove the pot from heat and skim any froth off of the top with a spoon. You can put the froth into a bowl and use for jam yourself. Removing the froth just makes the jars prettier.  Ladle the hot jam into sterilized jelly jars to 1/2″ head space.  Wipe rims of jars with a warm, wet cloth to remove any drips or oils from your hands.  Place lids that have been warming in hot water onto the jars. Add rings and tighten and then back them off a smidge.  Place in a waterbath canner of warm water and process for 15 minutes.  I also dehydrated a bunch of apricot halves. First, I cut the halves into a very large bowl and tossed them with a couple of tablespoons of Fruit Fresh. The apricots are not skinned.  I then toss about 1/2 cup of sugar into approximately two gallons of apricot halves because I like for there to be a little bit of a glaze when they are dried.  The halves are placed on the dehydrator trays. The trays have been sprayed with olive oil to keep the apricots from sticking.  I store the dried apricots in quart jars that have been vacuum sealed with a FoodSaver.  |

|

| |

|

Oklahoma Pastry Cloth™ Company on Facebook

|

|

|

|

|

|

Learning To Make Soap!

Monday, July 16th, 2012

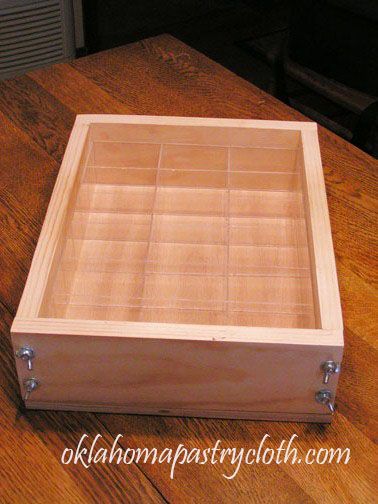

I assure you that this is going to be one, clean post. And yes, it’s about bars, but not the drinkin’ kind. I had so much fun the other day, I left in a lather. And, ok, I’ll stop now. What am I talking about? Last week, some of my friends and my daughter and I took a soap making class at the headquarters of Laughing Rabbit Soaps, under the tutelage of Charlotte Hayer. Charlotte is funny, excited about her craft and 100% on a mission to get others in Oklahoma to join her in soapmaking. For $25, we joined in the process of making 30 lbs of soap, each getting one pound to scent and color however we chose. One pound makes 4 bars of soap. And of course, you know me – I threw myself into the project with complete abandon, camera shutter flying. I am so excited about making a first attempt on my own. At that point, I’ll do a step-by-step. I am seeing all kinds of possibilities for soaps!! Just to let you see what we did, here are a few pictures.  First, Charlotte melted a mixture of solid fats and liquid fats in a large stockpot on the stove. She uses tallows or olive oil, palm oil, shea butter, cocoa butter, sweet almond oil, etc., depending on what type of soap she is making. She used a thermometer to determine that the temp of the oils was correct.  She showed us that there are all kinds of additives that one may use in soaps, including goats milk which should be added cold or frozen. She said that canned or cartoned goats milk can be employed if one does not raise goats.  Charlotte had mixed her lye into three separate containers of water several hours prior to our arrival in order for it to cool She did the three containers because she was making a triple batch of soap. She made sure that we understood that one always adds lye to water – not water to lye. The lye water was added to the oils.  Here’s something that I’m going to have to find because it works soooo well!! – A stick blender or wand blender to some people. The mixture of oils and lye were mixed together until it began to thicken and “trace”.  At this point, Charlotte filled plastic refrigerator containers with the liquified soap – one for each one of us.  We were given bottles of many types of essential oils, bags of ground flowers, herbs, cocoa and colorants. We used pipettes to transfer the oils to the soap and spoons for the dried materials and we just guessed at amounts.  As ingredients were added, the soap was stirred. I was amazed at how forgiving the soap is. We had plenty of time to make choices and experiment.  I added oatmeal baby cereal for gentleness, rosemary and peppermint essential oils, chopped vanilla bean for specks and cocoa for color.  The soap was covered to allow to cool slowly.  Charlotte used the leftovers to pour into one of her large molds. She colored her soaps with blue and pink, swirled. Very pretty.  Of course, Mr. Fix-It remains my hero. He helped me make my own mold for my first soap project and I think it is just pretty nifty. This mold will hold 4 lbs of soap and we will be making another one to match. I’m thinking of making a larger one as well. I have found my new adventure!! Stay tuned.  |

|

|

Oklahoma Pastry Cloth™ Company on Facebook

|

|

|

|

|

The Final Episode

Thursday, June 21st, 2012

For the past two days, I have been posting about my experiences with the medical community and autoimmune diseases. I am hoping that it reaches one person who can use it in their search for answers. Today is the last post on this subject and I will get back to normal stuff!! If you will remember, I ended the last post on a good note, thinking that all was cured and life was going to go back to normal. One might think that would have been the end of it. But no – there was much more to come. Within three months, my heart was racing, I was nervous, I chattered like a Magpie (I only chatter like a Mockingbird, normally) and I could leap tall buildings in a single bound, without the cape! I was hyperthyroid and getting more and more hyper by the day. A second endocrinologist took one look and said, “I’ve never seen anything like this. I don’t know that much about Hashimoto’s, but I’ve never seen anything like this!” That gave me great confidence in how my dollars were being spent and I opted for a third opinion. Endo number three determined that Endo number one had misdiagnosed me and that I actually had Graves Disease and not Hashimoto’s. I asked if one could have both. I have to admit here that I had done enough internet research to know that in rare cases, it is possible. This doctor declared, “Impossible!! They are mutually exclusive!!” He never called me to set up tests and never returned my calls to attempt to set up tests and so I figured that was another copay down the drain and that I didn’t want him either! It was at this point that I suppose I needed abuse to go on top of everything because I made an appointment with my cardiologist, in hopes that he would refer me to a young woman at OU Medical Center whose research on hyperthyroidism had intrigued me. I found her on the internet. Yes I did. In big, blue letters next to her name, the website indicated that she had only been in practice for 8 YEARS, like a warning to run from this sweet, young doctor wannabe. I was not deterred. My visit with the cardiologist began with the normal salutations and he asked me to give a synopsis of my concerns. I synopted and then made the mistake of saying, “I have been doing some of my own research on the internet and have read the book, “Hope For Hashimoto’s” when he looked at the ceiling and said – I kid you not – “Oh God help us!!” He lit into me like the Tasmanian Devil on Bugs Bunny only with gray hair and a stethoscope. Evidently, according to him, I am the kind of patient who wants to treat myself and looks things up on the internet to tell doctors what they need to be doing instead of just trusting them to take care of everything. According to him, I am a doctor hopper who doesn’t get the diagnosis I want and just goes to the next one because I have already determined my treatment. So what if the doctor is inappropriate, or admits ignorance or doesn’t even bother to set up tests? I should have just been satisfied to accept things as they are. He ended his tirade with, “STAY OFF THE INTERNET!!!” I reacted in the way that most women react. I’d like to tell you that I stood up, put my hands on my hips and told him that he was a jerk. I’d like to say that I grabbed my belongings and told him to take a flying leap. But I didn’t. I did what so many women do when they are mad – I cried. And I didn’t just cry. I hiccup cried. I sobbed. I told him that he didn’t know what he was talking about and that sometimes patients have really good reasons for seeking multiple opinions. He blew me off. He told me my heart would be fine, in spite of the high thyroid numbers, that I have Hashimoto’s Disease and that it is not possible to have both Hashi’s and Graves. He assumed that I was wanting a new endocrinologist and hinted that his desire was for me to see his friend of 30 years. I requested the sweet, young thing at OU and he balked. He explained that she had not been a doctor very long. I said that was fine. He said that his friend had been a doctor for very long. I said I didn’t care. He sighed and made the appointment. Then he walked out the door with a last, “Stay off the internet” admonition. I might add here that a few days later I wound up at the ER with Afib and a heart rate of 165 beats per minute, requiring Cardioversion which is basically shocking your heart back into reality. So he was wrong on that count too. I was sorely tempted for the ER doctor to add a note at the bottom of the charts to my cardiologist that said, “She checked on the internet and determined that her heart rate was too fast!!” But that would have been disrespectful….. I have now seen the young doctorette. She is awesome. She is kind, soft-spoken, well-educated and decisive in her observations. She explains in detail and lays out a plan. And she follows through! She even called me at home one morning to give me an update. Her diagnosis? That I have the autoimmune disease that presents itself as BOTH Hashimoto’s and Graves Diseases with both types of antibodies. I’m not nuts after all!!! So, bam, bam, bam, she has set up a million tests that have been taken, meds have been prescribed and I will also be doing a 10 day radiation treatment on my eyes for Thyroid Eye Disease in hopes of nipping that in the bud. It has been a long, long trip, but I feel like I’ve reached a destination point. This will be a life-long battle with my body, but I feel like I now have an advocate who will join with me in the fight. So don’t be afraid to take responsibility for your own health. Nobody cares about you as much as you do – except for God and He has given you the tools to make good decisions that lead you to better care. A great doctor is amazing, but, as in every profession, there are some not so great ones and you don’t have to be satisfied with not so great. I hope that you can gain something from my experiences. It will have been well worth it, then!! And I promise to do a demonstration post next!!  |

|

|

Oklahoma Pastry Cloth™ Company on Facebook

|

|

|

|

|

Homestead Revival

Homestead Revival Paratus Familia

Paratus Familia Rural Revolution

Rural Revolution