I’ve mentioned in past posts that I worked in the meat department of a grocery store in my previous life. At night, I helped cut and wrap custom beefs, lambs, hogs and deer. During the day, I was a butcher’s assistant, helping to cut, wrap and display all of the meats that were sold in the grocery. It was a fun job, believe it or not, made especially fun because of the people with whom I worked. It was a family operation and they treated their employees like members of the family. Practical jokes and laughs were a daily routine. One time, the butcher and his cousin had me convinced that I had guzzled Hydrogen Peroxide in my tea (the tea was fizzy), put there by a coworker who didn’t know any better, such that I was certain the stomach ache that ensued was due to gastric poisoning. There is a skull and crossbones on the bottle for heaven’s sake!!! I was handed the phone to call the doctor, who had been let in on the joke, and I was only encouraged further down the fantasy road of certain demise right there in the meat department. Finally, the giggles erupted and a bottle of Dr. Pepper was produced. My face could not have gotten any redder. I returnd the prank by heavily lathering the phone earpiece with vaseline and then calling the meat department from the phone at the front of the store. My boss answered the phone. Oh yeah. 🙂 I had to learn fast and hard in this job and being the competitive person that I am, thanks to the genes inherited from my tennis-playing grandfather, I was bound and determined to master whatever I was given to do. One of my first jobs involved wrapping the cuts of custom beefs in freezer paper and labeling the packages. It is a job that I still practice today every single time I freeze our own meats. There IS a method to wrapping! But that is for a later post. In my day job, the first task I was immediately tossed into learning was the job of cutting up a chicken. My first attempt was a joke, but as time went by, I got faster and faster and could finally cut and package a chicken faster than you could say “Cocka-doodle-doo”. This is a skill that has helped me more than you can imagine! Whether raising your own chickens for meat or purchasing yours at the grocery, knowing how to cut them quickly is a blessing. Today, I buy whole chickens on sale and cut them up, dividing them into packages of separate parts. The other day, I found whole chickens for 65¢ per pound. After cutting them, I packaged breasts together, legs together, thighs together, and packaged cut-up wings for hot wings, while cooking the backs, skin and “innards” for broth. A package of breasts for 65¢ a pound? Find THAT in a store near you! So here is the way that I learned to cut up a chicken. I learned from a pro – Greg, the Butcher! Thanks Greg, for all you taught me!!  You will need a cutting board that is not wood. Wood soaks up bacteria that is found in chicken and it is very difficult to disinfect afterward. You will also need a good boning knife that is sharp. I use Forschner brand knives which are the brand that we used in the meat department. I like them because the blades are flexible and can bend slightly. Also, if you like, you can do what we used to do in the meat department and use rubber dishwashing gloves. These help you hold the chicken easier to avoid slips, and you are less likely to cut yourself if you do slip.  With the breast side down, pull one wing out and away from the body and feel for the main joint. Slice between the two bones of the joint. You will slice down and around the joint bone.  Cut at the joint between the shoulder section of the wing and the “bicep” section of the wing.  Then cut between the joints that hold the “forearm” of the wing to the “bicep” section. I throw that little front part of the wing in with the back and other excess pieces to stew for broth. The two larger sections are packed together for “hot wings”.  Next, turn the chicken on its side and pull a leg up so that it is pulled away from the body. Slice your knife right through the center of the skin until you hit bone. Stop.  Using both hands, hold the body of the chicken and pop the thigh bone out of joint so that you see the end of it protruding.  Cut between the round end of the bone and the body to remove leg and thigh section. If you want to separate the leg and the thigh, on the inside of the leg and thigh section, using your first finger, feel for the indention that indicates the joint between the leg and the thigh. Slice between the two bones and separate the leg from the thigh.  Turn the chicken up on its front end and look for the soft section of skin between the back and the breast section. It is just a flap. Put the knife at a 45º angle to the back and slice in toward the backbone.  As soon as you hit bone, turn the knife blade down and slide the knife down along and between the backbone and the breast. There will be resistence because you are cutting through soft bone, but just push hard all the way to the end.  Repeat the same process on the other side of the backbone and lift the backbone out.  Now you are left with the breast section. If you like the ‘wishbone’ or your kids enjoy breaking it, simply turn the breast section over and slide your first finger down the center until you feel the tip end of the wishbone.  Cut straight down behind the bone tip and between the rest of the breast section and stop when you meet resistance.  Now turn the knife blade nearly parallel to the cutting board and slice along the front of the breast bone and under the wishbone.  Separate the wishbone from the breast  Turn the rest of the breast section on its back and cut right down the middle of the bone. This is soft bone and so with a sharp knife you can cut it. Start by putting the point of the knife down into the bone and press down. It will snap that top of the bone in two and then you can start cutting.  If you are like me and want to cut back on the fat and cholesterol of the skin, you can skin your pieces. This is a simple task, as the chicken skin easily separates from the meat. Just slide the point of the knife under the skin with one hand and with the other, pull the skin up to separate as you cut. And so there you have it – a totally cut-up chicken that you can now cook, can or freeze. I’ll show how I can mine in the next post and how I use it out of the jar. Once you have processed the main pieces, you can boil all of the leftovers into the stock found in this previous post.  |

|

Oklahoma Pastry Cloth™ Company on Facebook

|

Archive for the ‘Let’s Cook!’ Category

How To Cut Up A Chicken, Butcher Style

Monday, March 7th, 2011

Canned Broth

Saturday, February 26th, 2011

A reader of the very informative blog Rural Revolution, A. McSp, shared a wonderful recipe for chicken stock to be used for cooking pinto beans, soups – you name it. I decided to try it and am in love. First, the smell that permeates your house while cooking this stuff is enough to call Glade and ask if they make Chicken Stock in a Can Air Freshener, second, the flavor is so rich that it makes everything to which it is added have more body, and third, it’s canable – oh wait – that’s not a real word unless you’re talking about creepy hungry people and can’t spell. How about this: It can be canned! You know that always gets me right here (pointing to my heart now). I’m afraid that I was so involved in the process that I didn’t do my normal photo session and so I’m just going to have to give you the recipe with only a few photos and a video. Sorry for my brain freeze. I did get a couple of shots! Here are the steps to this amazing chicken stock! 1. When you cook a chicken, save the carcass, skin and all and if you aren’t going to make stock immediately, put it in the frig until you are ready, no more than a couple of days. 2. Cut or break the bones up into pieces using kitchen shears. 3. Put the bones and skin into a stock pot and cover with water, about a gallon plus. 4. Add 1-4 stalks of celery. I used my dried celery! 4 tbsp to equal 4 stalks. I love my dried celery! 5. Add 1/2 medium onion 6. Add 4-5 cloves of garlic 7. Add parsley if you have it 8. Add 1/2 tsp dill seed if you have it 9. Now here she said to add 1/2 tsp dried orange peel, but I didn’t have dried so I used 1 tsp of fresh orange zest. Oh my. I think I prefer that to the dried!! 10. Add 3 tbsp white vinegar and the juice of one half lemon or lime 11. Add salt and pepper to taste (side note: If you want an even more robust chicken flavor add 1/2 – 1 tsp granulated chicken bouillon per pint jar of stock) Bring to a boil and stew on low heat for two to three hours. The vinegar and the lime or lemon juice pull the calcium out of the bones and so your broth is rich in calcium. As the stock stews, I add a little water to maintain the water level. When the cooking time is reached, I pour the broth, bones and veggies into a colandar that is sitting over a large bowl or another stew pot, to strain the broth. I press the stuff left in the colandar with a potato masher to get out all of the liquid and flavor into the stock in the bowl. At that point, I ladel the soup into jars, leaving a 1/2″ head space, clean the rims of the jars, attach the lids and rings and put them into a pressure canner of hot water (the jars of liquid are hot and will crack in cool water) to be processed for 20 minutes at 10 lbs pressure. One chicken gives me 10 pints of broth.  Unlike waterbath canning, the water level in a pressure canner is only about 2″ deep.  The jars sit in the water, but are not covered by it as in a waterbath. I did a video of the pressure canner as it was doing it’s thing this afternoon. I’ve had several people ask me how it is supposed to sound. If you will notice, it jiggles for a bit and then stops and then jiggles and stops. That is the rhythm that you want to achieve to keep an even pressure. I start out on high heat and when the weight starts vibrating, I start turning the heat down until I get a uniform rhythm. I bought this canner in 1977! It has been a jewel. Pardon the noise of the microwave in the background. Halfway through I realized it and turned it off! Last night, I made pinto beans with two pints of broth, two tbsp brown sugar and a slice of home-cured country ham. Oh my. I’m still grinning. |

|

Oklahoma Pastry Cloth™ Company on Facebook

|

Canning Butter

Thursday, February 24th, 2011

|

I have a question. If milk is nature’s most perfect food, as we ALL learned in our science classes many years ago and have heard on many a dairy commercial, why isn’t butter perfect too? Why has butter gotten such a bad rap when it is simply the richest part of the milk that has been whipped to a frenzy? All I know is that butter is all-natural and has to be a whole lot better for you than the fake spreads that marketers have tried to pawn off on us as the nutritionally better alternative. We humans seem to always go down the road of trying to improve on what comes naturally and then wind up right back where we started, concluding that the original product isn’t so bad after all.  I have admitted my affinity for butter in past posts but I am in no way an addict to the stuff. Really. I can quit using it anytime. Really. I use it in moderation mixed with olive oil and am known to spread it sparingly on a slice of fresh homemade bread. Really. But there is simply no substitute for the stuff when it comes to sauces, cajun cuisine and toast.  So did you hear about the solar flares that scientists are afraid are going to destroy the earth? Well, not destroy exactly…just leave us in an electronic lurch which would pretty well destroy the majority of us who can’t live without a cell phone, computer or electric toothbrush. How in the world can I keep my precious butter from spoiling if our refrigerators aren’t running? Well, I can it, silly! I gathered all of the info I could from several sources on the internet and have started canning part of my butter when I find it on sale. The Indians in India have been canning clarified butter, called ghee, for ages and ages. I like to can my butter whole. Take a peek at what is working for me:  Wash jars in hot soapy water and boil in a large pot or wash on the sterilize cycle in the dishwasher. Place the jars on a cookie sheet. Here I am using 8 oz jars which hold about 1 1/3 sticks of butter. In this run, I used 9 – 8 oz jars for 12 sticks of butter or 3 lbs. Put the cookie sheet of jars into a 250º oven and heat for 20 minutes.  Place sticks of salted butter in a large pan. I do about three pounds at a time simply for ease. The larger pots get too heavy to manipulate and butter gets everywhere.  Slowly melt the butter on medium heat, stirring constantly with a metal spatula to keep from scorching on the bottom. A spatula with holes is ideal because the melted butter is pushed through the holes during stirring and helps to keep it uniform.  When the butter is totally melted but not quite boiling, continue to stir and allow to simmer for 10 minutes. A thick, white foam will appear.  While melting the butter, place lids in a pot of water and bring to a near boil to prepare lids. Turn heat down to keep lids warm.  Remove jars from oven and immediately ladel butter into the jars, using a canning funnel. Be sure and stir the butter around and dip deep, pulling up, in order to keep the butter uniform, as it separates. Fill to leave a 3/4″ head space.  Carefully wipe the edges of the jars with a damp cloth to remove any butter. Butter on the rims will cause the jars not to seal.  Place the lids on the jars and attach rings, tightening slightly. Place jars into a waterbath canner that has water already heated and enough to cover the jars 1″. The water needs to be heated because the jars of butter are hot and will crack in cool water. As soon as water begins to slowly boil, set timer for 15 minutes.  When jars have been processed for 15 minutes, turn off heat and allow to cool down in the water for another 10 minutes. Then, lift the rack to top of canner and remove jars with canning tongs.  When the jars are cool enough to handle, now comes the tedious part. Every few minutes shake the jars up and down in order to make the butter uniform. If you notice in this photo, the jars to the left have sediment on the bottom and foam on the top. Shaking incorporates this into the clarified portion. Go about your business, but about every 5 minutes, stop and shake the jars. As they cool, they will stay more and more uniform. I set a timer to remind myself so that I can do clean-up.  This butter is totally cooled and ready to store in the pantry. Aren’t they pretty? I read one homesteader’s take on canning butter and she said that they actually opened some from 1999 and it was still good. Don’t think I would keep it THAT long, but it wouldn’t matter because it wouldn’t last that long around here anyway!!  Canned butter is not quite as smooth as fresh butter, but if you are wanting a smooth, healthy spread, you can make the same recipe posted earlier with olive oil or canola oil. Just scrape butter from an 8 oz jar into the food processor or blender.  Add 1/3 cup oil. If you have canned your butter in larger jars, adjust amounts of oil. For example, a 1 pt jar of butter would require 2/3 cups of oil.  Process until smooth  Pour back into jar and allow to harden in the frig. It will go back to the consistency of smooth, spreadable butter. Pass the Lobster, please!! |

|

Oklahoma Pastry Cloth™ Company on Facebook

|

Hashbrowns! Yum!!

Friday, February 18th, 2011

|

Is Misspelled…  It’s closing in on planting time for potatoes! I love fresh potatoes from the garden and have done posts before on them. I am planning on doing a full bed of the knobby things this year. Usually, we only do a half a bed, but we were out of potatoes too soon this time. And of course, I’ll be drying some of them. But I have another favorite way to prepare potatoes for the long haul and I have been asked by reader, Shari, to share it here. Mr. Fix-It loves hashbrowns and it is easy to take a large batch of either garden potatoes or Russets from the store and make hashbrowns to last you a long, long time.  First cut up potatoes to fit into a food processor with a grating blade on it. You can also grate them by hand. Red and Yukon golds can keep the skins, but Russets are better peeled  Put into a food processor to grate or do it by hand  Once the potatoes are grated, put them into a collander that is in a larger bowl and pour water to cover the potatoes. Pick up the collander and swish it up and down. The water will be white and cloudy. Pour that off and do the same process until the water is clear. This washes off all of the starch that makes potatoes turn black.  Lay a large bath towel out on the counter and spread the grated potatoes over the towel.  Fold the edges of the towel over the top of the potatoes and roll the towel up like a jelly roll, pressing as you roll. This squeezes out excess water. When you unroll it, the potatoes will be dry.  Distribute the grated potatoes among cookie sheets and place in the freezer.  Remove from freezer and, using a spatula, lift potatoes off of the cookie sheets.  Place in plastic freezer bags  Bend the bags around to break up the slabs of frozen potatoes. Label bags and place in the freezer.  Your hashbrowns can now be used in any recipe calling for hashbrowns, even casseroles. To make old-fashioned hashbrowns for breakfast, put 2 – 6 tablspoons of oil (depending on the size of your skillet but barely covering the bottom), either olive oil or vegetable or coconut, in the bottom of a large skillet and heat on medium high. When heated, add hashbrowns to about 3/4 – 1 inch deep and salt to taste.  Cover with a lid and cook until the bottom of the potatoes is golden brown.    Cook until the second side is browned and crisp. Remove from the pan and pat with paper towels to remove any excess oil. Serve as a side dish. And don’t forget the grits!! |

|

Oklahoma Pastry Cloth™ Company on Facebook

|

|

|

Yep!! Canning Cheese

Wednesday, February 9th, 2011

I’ve always heard that “necessity is the mother of invention” but I also think that it is “the mother of learning something new”. Such was the case recently after a productive trip to our local grocery which is owned and operated by the Absentee-Shawnee Indian Tribe. On this particular day I discovered that the store had block cheese on sale; 1 8oz block for $1. Never one to pass up a good deal, I decided that if one block of cheddar was good, 20 blocks of a variety of cheese was phenomenal! I tossed mild cheddar, mozzarella, sharp cheddar, pepper jack and cojack into my cart and trotted on down the isle. To my surprise, I found that Velveeta was on sale too. Oh joy. Now, I must digress here for a sec in defense of Velveeta cheese PRODUCT. Although I realize that Velveeta is the plasticized version of cheese, it is a must for any kitchen simply because it melts sooooo smoothly. It is wonderful for cream soups. It is true that nobody REALLY knows where Velveeta comes from. And while we are told that it is made from milk, it could be guinea pig milk for all we know. However, while we ponder how one milks a guinea pig, the rest of America is enjoying its queso made with Velveeta, picante sauce and maybe some ground beef flavored with taco seasoning. Velveeta is to the cheese world what Spam is to the ham world. Each has its purpose. And so, I got my Velveeta and checked out. On my way home, it occurred to me that all of this cheese had to have a place to go to stay fresh. I usually grate my hard cheese, put it into bags that I can vacuum on my FoodSaver sealer and then freeze it, but this was going to be an enormous amount of grated cheese. What if I wanted sliced cheese? My experience with freezing blocks of cheese for slicing had been less than successful. I had been totally unhappy with frozen Velveeta, so what to do? What to do? Thank goodness for the Internet. Enola Gay at Paratus Familia had the solution. Can it! Can cheese? Really? She showed how to can hard cheeses and that got me to thinking about canning the Velveeta too. I researched and researched and found several ways to do that as well. I wound up with what I think worked best for me. So first, I’ll show you how I canned the hard cheeses and then the Velveeta. Talk about handy. You can’t believe how wonderful it is to have canned cheeses. You can shred and slice the hard cheese and the Velveeta is just as good as if it were in the box. I suppose at this point I should throw in the disclaimer that I haven’t found anything that indicates the government watchdogs have given their seal of approval to this, but then, they don’t like us canning apple pie filling either. From everything I have read, these canned cheeses last up to two years.                    Oklahoma Pastry Cloth™ Company on Facebook

|

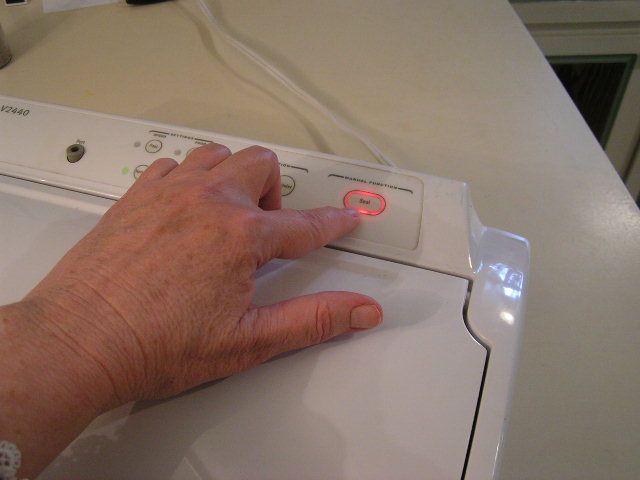

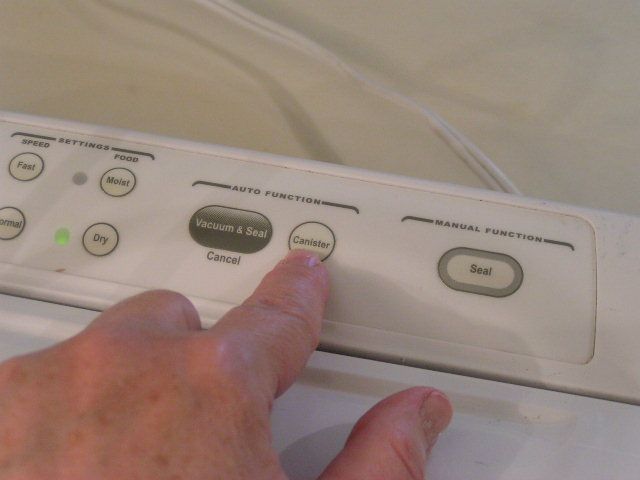

Vacuum Sealing Jars

Saturday, January 15th, 2011

|

|

|

Oklahoma Pastry Cloth™ Company on Facebook

|

|

|

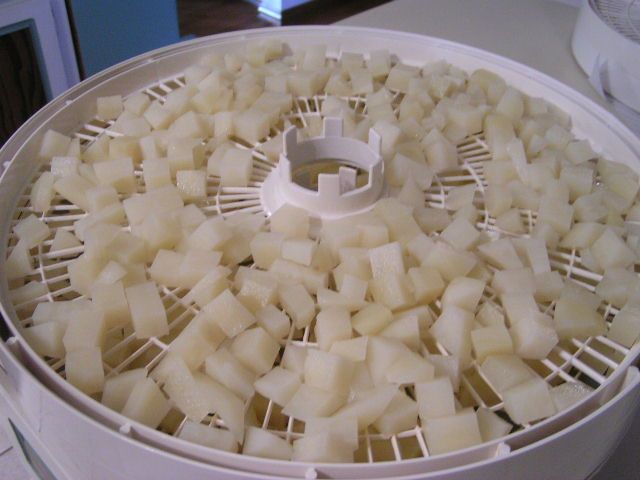

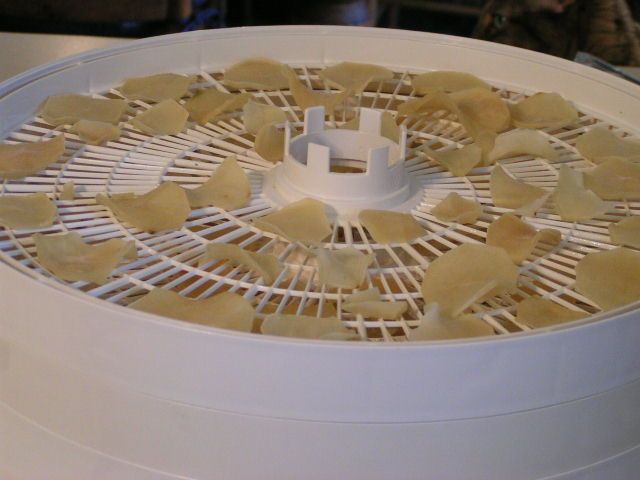

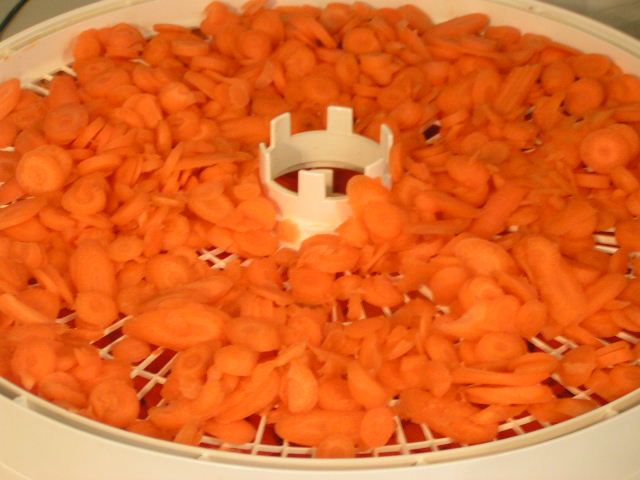

Dehydrating Series Pt II – Potatoes

Thursday, January 13th, 2011

I’m going to get right to the point today as a continuation of Part I with photos of how to dry potatoes. Potatoes are one of my favorite garden items and I devote an entire bed to both red and Yukon Gold spuds. These “new” potatoes take a little longer to dry than the traditional Russetts which I am demonstrating here. Also, at the end is a recipe in which to use the sliced and dried potatoes. My next post will be about drying peppers and then you’ll get a recipe for broccoli cheese soup made from all of your dried veggies that will have your family licking the pot. So keep following!              (Or as my friend Janis calls them, “Old Rotten Potatoes”) 1 pkg Shawnee Mills Country Gravy Mix 2 1/4 cups water OR make 2 cups of your own white sauce from your favorite recipe 1 cup dried sliced potatoes 1/2 medium onion 1/2 cup shredded cheddar cheese 2 tbsp Hormel Real Bacon Bits or 3 slices bacon chopped into pieces French’s French Fried Onions          |

|

Oklahoma Pastry Cloth™ Company on Facebook

|

|

|

Homestead Revival

Homestead Revival Paratus Familia

Paratus Familia Rural Revolution

Rural Revolution